Series 970 Hydraulic Test Stand Heavy duty, variable frequency drive for testing pumps with the most demanding applications.

Series 970, Hydraulic Test Stand

The Series 970 hydraulic test stand features precise digital invertor, RPM control, all digital gauges, stainless steel construction, and Kidney loop pump for continuously filtering and cooling of hydraulic fluid.

Our competent engineering staff ensure you are provided with the exact hydraulic test equipment for current and future applications which will increase your profitability.

Standard Features & Specifications

Hydraulic Test System

APD� Monitoring System with Data Acquisition:

- * Will Save Time and Money

- * Insure Compliance with FAA Regulations and OEM Test Requirements

- * Provides a Convenient and Easy to Understand Method of Testing and Reporting

- * Produces Accurate Records for Stored Data for FAA Audit Compliance and Accountability

- * Eliminates Hard to Support Component Testing Procedures

- * Easy to Interpret Strip Chart That Displays Pressure, Flow and Temperature Simultaneously

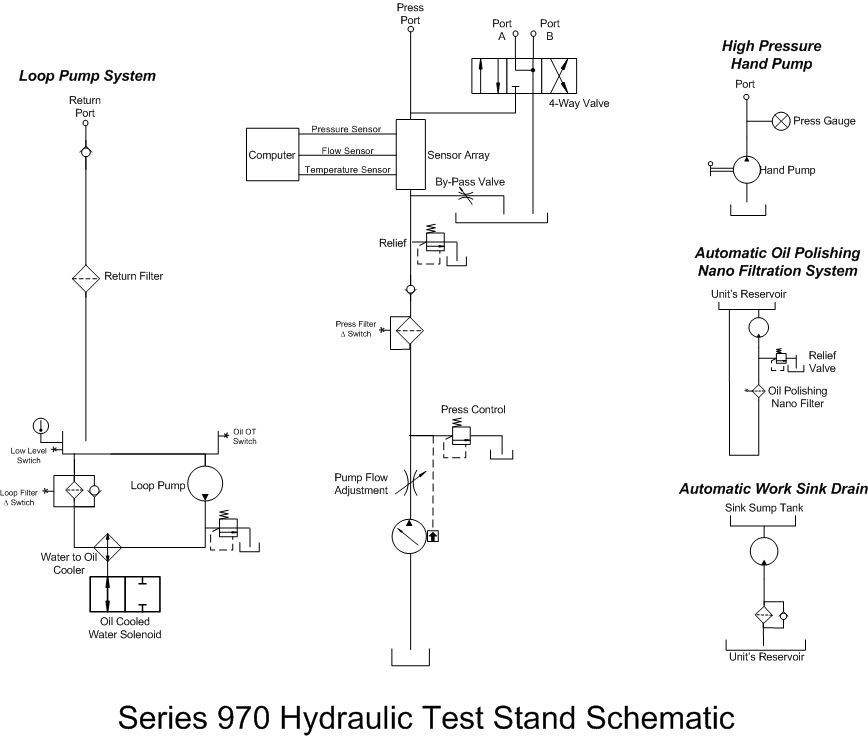

STANDARD FEATURES:High Pressure Hand Pump

1. Digital Pressure Gauge (.25% Accuracy)

2. Pressure Release Valve

3. Dedicated Port

Super Clean Filtration

- Industry Leading

Filtration Ensures Quality While Increasing

Aircraft Component Life and Decreasing

Aircraft Filter Changes

High Efficiency,

Non-Bypass Pressure Filter

(3 Micron Absolute)

Reservoir Kidney Loop

Filter (3 Micron Absolute)

Sink Drain Filter (3

Micron Absolute)

Exclusive Automatic Nano

Filtration System

(.25 Micron Absolute)

4-Way Directional Flow

Control Valve

Electrically Operated with Port Indicator Lights

for Testing Cylinders

Calibration

Calibration parameters are

stored in the electronic

interface and the software automatically reads the

calibration parameters from the devise when launched

Operator can adjust the

sensor parameters during

calibration for the correct accuracy needed

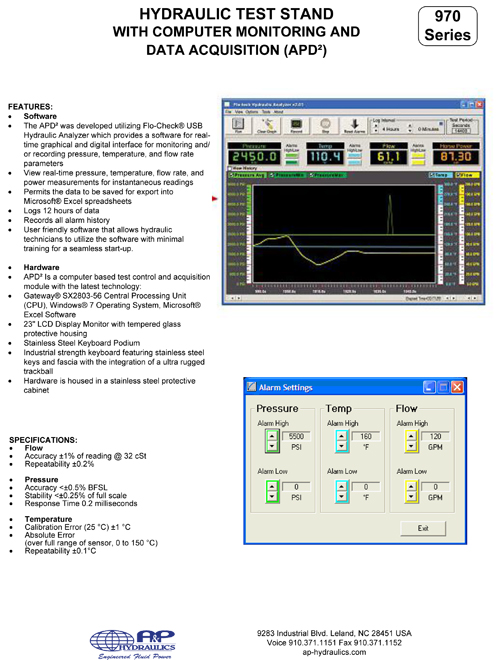

Software Parameters

Main screen displays strip

chart enabling the hydraulic

technician to have a more in depth understanding

of the operation/test procedure and troubleshooting

of the component under test

Color coding of the

parameters are easily read

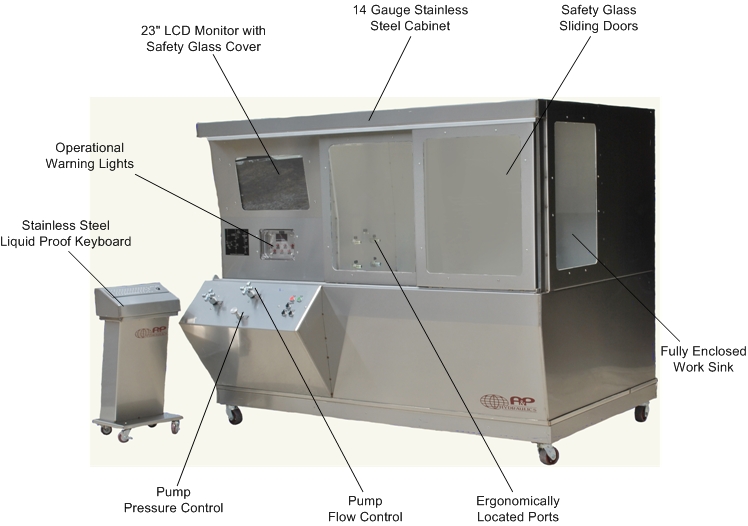

- Panel Mounted Pump Controls for Ease of Operation and Safety

- Safety Glass Sliding Doors

with �” Tempered Glass

with Heavy Duty Door Rollers and Rails - Complete Pump Pressure Adjustment (450 – 5000 PSI)

- Complete Pump Flow

Adjustment (0 – Full GPM)

- Five Pumps

1. Oilgear� Pressure Compensated Pump

2. High Pressure Hand Pump (10,000 PSI)

3. Work Sink Drain Pump

4. Automatic Nano Filtration Pump

1. Digital Pressure Gauge (.25% Accuracy)

2. Pressure Release Valve

3. Dedicated Port

Filtration Ensures Quality While Increasing

Aircraft Component Life and Decreasing

Aircraft Filter Changes

(3 Micron Absolute)

(.25 Micron Absolute)

Electrically Operated with Port Indicator Lights

for Testing Cylinders

interface and the software automatically reads the

calibration parameters from the devise when launched

calibration for the correct accuracy needed

technician to have a more in depth understanding

of the operation/test procedure and troubleshooting

of the component under test

- Software Includes

- Viewing of Graph History

- Displaying and Hiding of Individual Graph Plots

- Adjusting Graph Scale

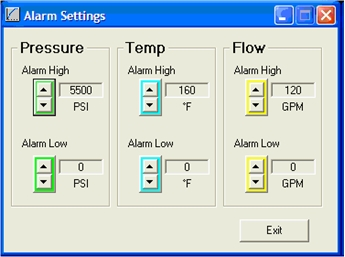

- Changing Alarm History

- Data Acquisition

- Operational Warning

Lights

- Pressure Filter Condition LED Indicator

- Kidney Loop Pump Filter

Condition LED

Indicator - Reservoir Low Level LED Warning Indicator

- High Fluid Temperature LED Warning Indicator

- Nano Filter Condition

LED Warning Indicator

- Reservoir Kidney Loop Pump

- Continuously Filters Fluid

- Continuously Cools Fluid

- Automatic Oil Temperature

Control

- Oil Polishing System

- Extremely Clean Nano

Filtration with Automatic

Timer and Operation LED Warning Indicator

- Additional Features

- All Welded, 14 Gauge B3

(Brushed Finish)

Stainless Steel Cabinet - Illuminated Work Area

Provided By the Over

Head Work Sink Lights - Easy Access Fluid Sample

Port to Meet

Quality Parameters - Guaranteed No Leaks

Safety Drip Pan Completely Covers Bottom - Work Sink with Perforated Metal Grating

- Heavy Duty All Welded 1/4"

Thick Wall

Tubing Frame with Fork Lift Brackets - Easy Maneuvering Ensured

By Two Fixed and

Two Swivel Castors with Stability Provided By

the Heavy Duty Floor Lock - Work Sink Drain Pump with Filter (4 GPM)

- Durable Laser Engraved, Aluminum Placards

- Panel Mounted Operational Instructions

- Current Pressure Gauge and

Flow Meter

Certificates of Calibration

- Safety Features

- High and Low Pressure Alarm

- High and Low Flow Alarm

- High and Low Oil Temperature Alarm

- System By-Pass Relief Valve (7500 PSI)

- Safety Glass Doors to Protect Operator

- Isolated Work Sink – No

Hydraulic Controls Located

with in Sink Area

Dimensions:

Model Series 07-972-**, 07-973-**, 07-974-**:

Length 100 in (254 cm), Width 62 in (157 cm), Height 80 in (203 cm)

Model Series 07-975-**:

Length 120 in (305 cm), Width 80 in (203 cm), Height 80 in (203 cm)

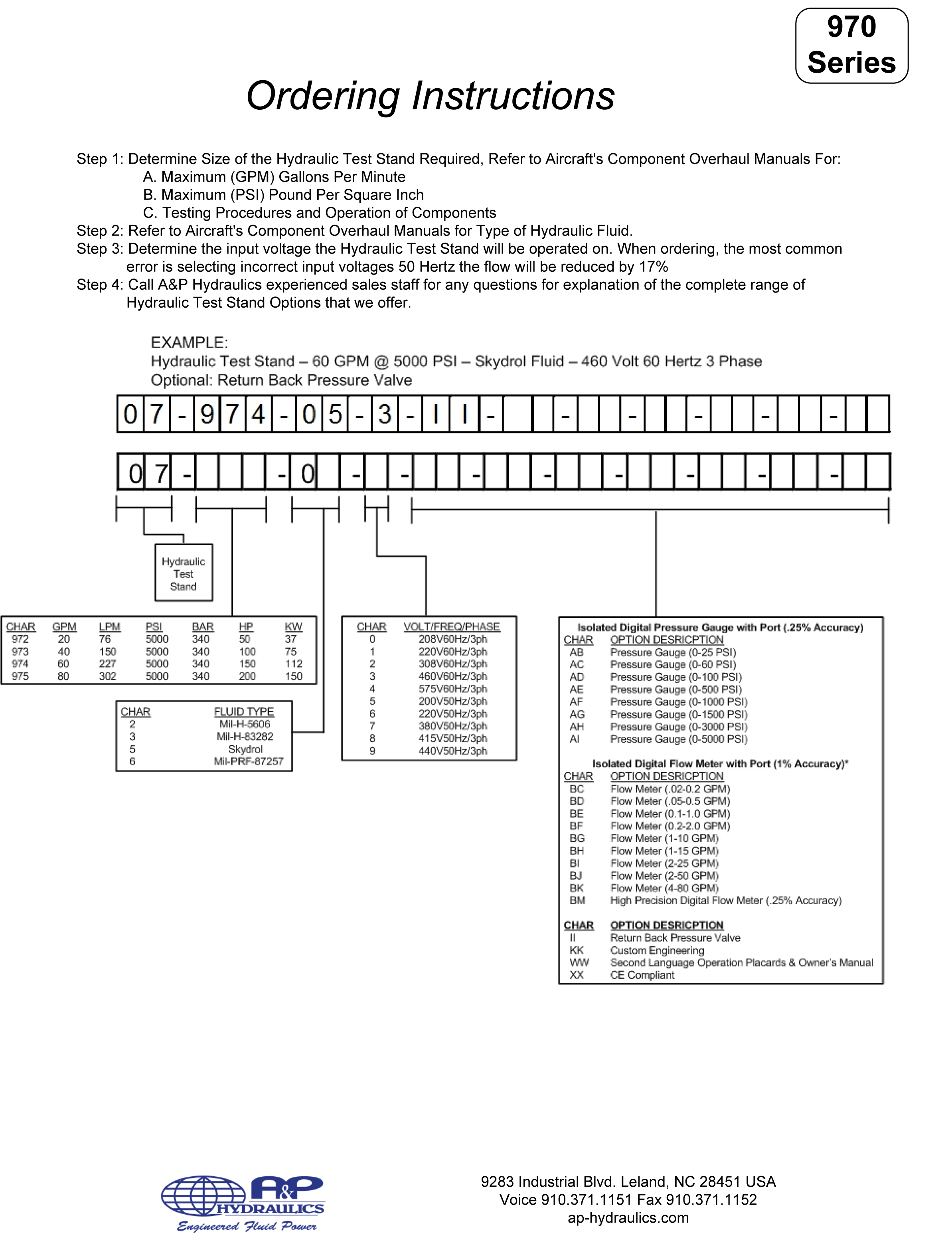

FEATURES:

- Software

- The APD� was developed utilizing Flo-Check� USB Hydraulic Analyzer which provides a software for real-time graphical and digital interface for monitoring and/or recording pressure, temperature, and flow rate parameters

- View real-time pressure, temperature, flow rate, and power measurements for instantaneous readings

- Permits the data to be saved for export into Microsoft� Excel spreadsheets

- Logs 12 hours of data

- Records all alarm history

- User friendly software

that allows hydraulic technicians to utilize the software with

minimal training for a seamless start-up.

- Hardware

- APD� Is a computer based test control and acquisition module with the latest technology:

- Gateway� SX2803-56 Central Processing Unit (CPU), Windows� 7 Operating System, Microsoft� Excel Software

- 23" LCD Display Monitor with tempered glass protective housing

- Stainless Steel Keyboard Podium

- Industrial strength keyboard featuring stainless steel keys and fascia with the integration of a ultra rugged trackball

- Hardware is housed in a stainless steel protective cabinet

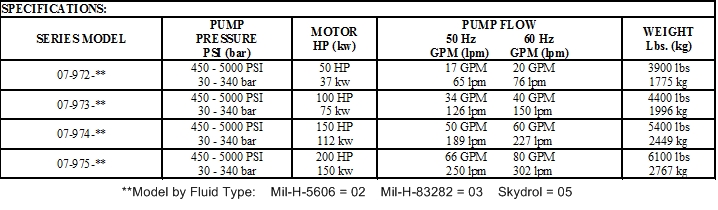

SPECIFICATIONS:

- Flow

- Accuracy �1% of reading @ 32 cSt

- Repeatability �0.2%

- Pressure

- Accuracy <�0.5% BFSL

- Stability <�0.25% of full scale

- Response Time 0.2

milliseconds

- Temperature

- Calibration Error (25 �C) �1 �C

- Absolute Error (over full range of sensor, 0 to 150 �C)

- Repeatability �0.1�C